|

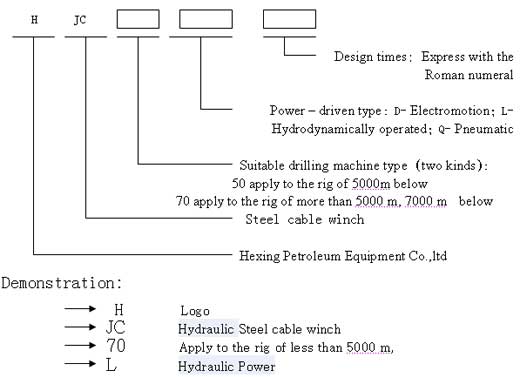

Ⅰ、The explanation of serial number

Ⅱ、Voluntary standards

Name:Hydraulic Steel cable winch

Design code:Q/LHXS01-2008

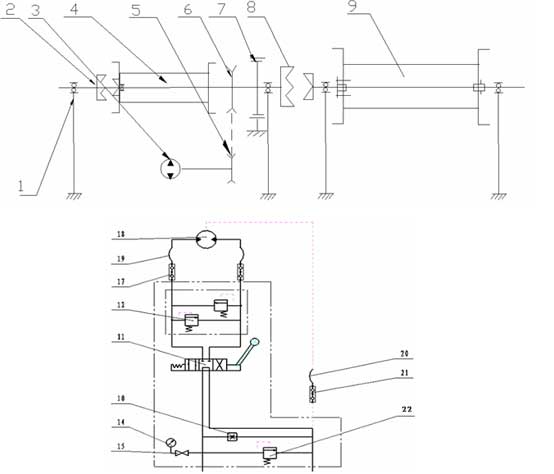

Ⅲ、Transmission schematic diagram

HJC-70 Hydraulic Steel cable winch –principle of hydraulic transmission

HJC-70 Hydraulic Steel cable winch –principle of hydraulic transmission

HJC-70 Hydraulic Steel cable winch –principle of hydraulic transmission

Ⅳ Operational principle

HJC-70L hydraulic Steel cable winch which is a mechine of hydraulic-mechanic transmission changed the heavy hard rope-pulling work to hydraulic transmission.This mechine is HJC-70L hydraulic rope winch which producted by our factory.The basic principle of this mechine shown as figure of transmission.

4.1Basic element

4.1.1 Transmission system is made up of hydraulic motor,chain transmission pair 5&6, rope-reel 9 which needs consumer self-provided,citation rope reel 4,single-jaw clutch 2&8,fixed support 1 and so on.

4.1.2 Rope-pulling system is made up of citation rope reel 4 and single-jaw clutch 2. Reeve rope system is made up of single-jaw clutch 8 and the reel 9 that consumer self-provied

4.1.3 Hydraulic control system is made up of manual valve 11,speed control valve 10, pressure regulating valve 22,manometer 14,manometer switch 15,sequence valve12,high pressure hose19&20,quick connector17&21

4.1.4 Pedestal and bearing:Bearing which uesed on citaton rope reel and spear cable reel connected with pedestal 1 which is formed with H-type steel

4.2 Working princple

HJC-70L Hydraulic Steel cable winch use the high-pressure pipeline which was equiped to hydraulic big clamp connectted to hydraulic cable winch’s control valve .The high pressure liqied output by hydraulic big blamp’s pump drives hydraulic cable winch’s motor rotate,then to the reel that belongs to citation rope reel or big rope reel(cable reel)complete the work of rope-pulling or rope-reeving

4.2.1 Rope-pulling work:Make single-jaw clutch 8 connected,run the hydraulic control organization,orperate the manual velve 11.The pressure liquid will going into the motor 18 and make it rotate,then to the spare cable reel 9 making the cable rolled back.

4.2.2 Rope-reeving work:make the single-jaw clutch 2 connected and 8 disconnected,run the hydraulic control organization and operate the manual velve 11.The pressure liquid will going into the motor 18 and make it rotate contrary,then make the reel 4 rotated rolling the cable,thereby making the big cable into the crown block swimming pulley to compelete the reeving work

Ⅴ.OPRATION INSTRUCTION

5.1 Praparing

(1)Settle down the hydraulic cable winch equipment steadily below the derrick floor sideway

(2)Connect high pressure pipeline one end to hydraulic big clamp’s pump and the other end to the hydraulic cable winch

(3)Check the pressure pipeline connector has connected correctly and firmly,check the oil pump is at running state.

(4)Make sure all the staff evacuated from oprating eara before rolling cable work

(5)When working must have one man to operate the hydraulic system ,one man ovservate and conductor

5.2 operating instructions

(1)When pulling the big cable,make sure there is no trespassers in the derrick floor’s front eara, Loose the big cable from the drilling mechine and the rope death,must follow the requiment bundle the cable end with hemp palm cable for guiding,then connected single jaw clutch ,and loose the handle of break which control the deputy reel,operate manual velve and run the hydraulic motor,making the cable reel rotated slowly pulled the big cable back until all the cable has rolled to consumer’s self-provided reel.

(2)When reeving work,first,making the guide rope to a postion where is convinent to oprating with the pulleys.Then,roll the guiding rope through the rope-system made by swimming pulley and crown block,connecting the rope conecting sleeve with big cable’s end.Then connected single jaw clutch to guiding rope reel and made the big cable reel under the free-storkely state.When make sure there is nobody in the oprating eara ,free the break of the deputy reel,and oprate the manual velve to run the hydraulic motor,make the rope guiding reel rotated and rolled up guiding rope,thus make the big cable into the swimming pulley system.When finished make sure the other end of the big cable fixed on drilling mechine’s reel and fixed rope death

(3)After oprating ,make the break working ,holding the main shaft.

Ⅵ、The advantage of HJC-70L Hydraulic Steel cable winch

1、Winch brake often closed state agencies, start braking when should first pull down the handle, brake release, before they start hydraulic motor

2、The device have smooth operation, speed adjustable, good adaptability。

3、This kind of device is in the position of initiating in the territory of wearing the steel rope and shaking off the steel rope at home. There is no precedent both at home and abroad at present.

4、This device has lightened the labor intensity of drilling crew's workers by a large margin, improved working efficiency, shorten the time of moving nearly one day.

5、HJC-70L Hydraulic Steel cable winch, FrameCompact ,It is convenience to move for Well Team, transportation, installation ,maintenance and use for it ..

6、Technology is ripe, dependability is good, ordered by a large margin , respond well at the scene, welcomed by the header of drilling crew, workers and well drilling company deeply.

Ⅶ、Basic parameters

|

HJC-70L Hydraulic winch |

|

Type : HJC- 70 L |

Speed of output lines 0.25-1.0 m/s |

|

Effective load:12000 kg |

Turning diameter: 2140 mm |

|

Power of oil motor:37kw |

Rated output torque of oil motor:5763 N. M |

|

Maximum tension stress of winch:16 MPa |

Stress of oil motor: 20 MPa |

|

Displacement of oil motor: 2267 ml/min |

Rotational speed of oil motor:0-75 r/min |

|

Maximum tension stress of winch: 23800N |

Weight: 2900 kg |

|

Executive standard: Q/LHXS 01-2008 |

External dimension:3593×2200×1750 |

Attention must be paid to the following:

1.Nozzle should be sealed and rolled at diameter 600mm for keeping and transporting when hydraulic lines was leaved unused .

2、When take out of drilling line, must bind fast line with coir rope by rule, and then fix after stripping fast line, after inspecting all of people leave the well field, can begin cutting off drilling line operation.

3、46# Anti-wear hydraulic oil was used in the Hydraulic System, change hydraulic oil in April and October per year.

4、System bearing seat should be used calcium-based grease and add every 3 months

5、Stop winch when shifting gear. In the process of transiting, claw and swift should be transported hang and shut in case of rotating.

Ⅷ、Ordering notice

1、Consumer should declare position of gear, power, speed of rotated gear if have ad hoc request when ordering

2、Several colors offered below when ordering.

|

Content

Colour

Sequence

Number |

Mainframe |

Roller |

Chain block |

|

1 |

Eggshell cyan |

Black |

Red |

|

2 |

Nacarat |

Black |

Red |

|

3 |

Blue |

Black |

Yellow |

|

Explaination:If consumer do not have any other declaration when ordering, we will match colors according to sequence number 1, and also can declare if want to have distinctive color. |

|